This weekend is three weeks since I first heard the strange noise coming from my new Westerbeke diesel engine. This Monday will mark three weeks since I started calling the local San Diego distributor of Westerbeke, A to Z Marine, and asked for help. Technically we are no further along now than we were three weeks ago. After a year of planning and weeks of preparation Astraea sits all fueled and ready to sail to Mexico yet we just sit in the marina and wait..... and wait...... and wait. Everyone tells me that I am fortunate that this happened in San Diego and not in Mexico, however I am beginning to feel like San Diego is a third world country as far as getting anything done on my engine.

The West Coast Westerbeke representative told the San Diego people at A to Z that they were certain that I had a classic and apparently common case of what he called "injector knock". He said that apparently I had gotten some contaminated fuel and the contamination had gotten to the injector and fouled or damaged the injector and this was causing the knocking sound. I found this difficult to accept in that I had only purchased fuel twice since the engine was new, one time in San Francisco and the other time in Half Moon Bay. Both fueling depots were in excellent marinas and operated under brand names. Also, the new engine has a top of the line dual Racor filter system with 2 micron filters, plus there is a 5 micron filter on the engine. It did not seem possible that any contamination could have gotten through the gauntlet of those filters. However as this guy is the West Coast honcho we had to wait until he had someone come out to do another test. This test was to swap the injectors from cylindar one and four. If after swapping the injectors the knocking sound moved from cylinder four to cylinder one then it would be apparent that the problem was the injector. This would simply require the injector to go to the injector shop for inspection and repair or replacement. Simple.

However Thursday the A to Z Marine people told me that a third master mechanic specializing the Westerbeke engines was coming to the boat on Friday morning to swap the injectors for this test. I drove to San Diego the night before in order to be there when they arrived. As promised the mechanic, Roger, showed up on Friday morning and swapped the injectors. He then bled the engine fuel system of air and then we started the engine. Unfortunately swapping the injectors resulted in no change in the engine nose. The knocking was still coming from cylinder four.

In three weeks we have had three master mechanics sent by the Westerbeke reps come to the boat and do tests. All three have now come to the same conclusion, that cylinder four has a bad rod bearing, bad rod connector, or other serious problem in the cylinder that, if not corrected, will result in throwing a rod through the side of the engine.

A to Z Marine promised to get back to me late last Friday (which they did not) or this coming Monday with further guidance from the West Coast Westerbeke rep. I am beginning to worry about how long this is all going to take to just get authorization to fix this problem. I have requested a new engine. If this engine failed at 180 hours with a bad bearing then what is to say the other bearings will not also soon fail? Also, trying to repair this engine would be a major job, much more complicated than just a swap out for a new engine. The engine would have to be disconnected, lifted off it's engine mounts and up into the main salon, and then disassembled, inspected, repair parts obtained, engine reassembled, lowered back into place, reconnected, and tested. I would have very little faith in the engine after having it all disassembled and reassembled, therefore I want a NEW ENGINE!

I am anxious to get this whole project quickly started as every day of delay is another day in the Mexico cruising season lost forever. Also, I have missed the Baja Haha, which I had been anxious to be in for the past year; I lost my crew, and they lost their airline tickets back from Mexico. I have also lost my non refundable marina depost of $600 for LaPaz, and my ticket back to Palm Springs from Cabo for the holidays. Lots of plans and lots of dollars have been lost due to this engine failure. Counting additional marina fees in San Diego, lost deposits, lost airline tickets, wasted Mexican insurance fees, etc., so far this little debacle has cost me about $4000 in direct costs, not to mention the loss of cruising time...... which is priceless.

What is really frustrating is that I spent $40,000 for this new engine just so I would not have to worry about problems like this. I bought Westerbeke due to their excellent reputation and my experience with them in the Navy. To have this happen is disheartening and disappointing, to say the least.

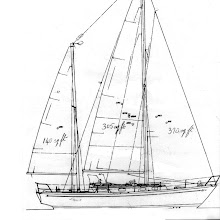

To see what this entailed click here for pictures and description of installing this new Westerbeke engine.

I am attempting to be patient and polite, however thre weeks have passed and I have gotten nowhere other than three different mechanics coming to the same conclusion. If something definitive does not happen soon then I am going to have to decide what step to take next. I am still hopeful, however, that Westerbeke, who has been in the marine diesel business since 1937 and is an American company, will step up to the plate and do what is right: move quickly to fix a serious problem with an very expensive engine that is still under full warranty.

Weserbeke, please do the right thing!!!!